VDL Weweler-Colaert

VDL Weweler-Colaert

Parabolic springs

WEWELER® leaf springs are redesigned to suit specific vehicle models and specific operational areas. This means that even if another spring looks the same, there is a risk that it will offer poorer comfort, payload, drivability and last but not least: LIFETIME. The high quality and long service life of WEWELER springs assures comfort and road holding needed for safe and economical transportation work in an environment friendly way.

To the naked eye, most leaf springs look more or less the same. It is only when you study the materials from which they are made and the production process used in their manufacture, that the difference becomes apparent.

Thanks to strict dimensional precision as per OE specification, WEWELER springs are quick to install. In addition, WEWELER springs are equipped with high quality silent blocs and accessories. VDL Weweler-Colaert has conceived a new type of silent bloc, which by its geometry assures comfort an improved road holding. The concept of the insertion into the eye, guarantees a better repartition of the traction and the torsion forces on to the main leaf, which improves the endurance and the performance.

Water-based paint is applied with special paint spray guns and is used as a standard for all WEWELER parabolic springs and trailing arms. The anti-corrosive properties are even better than most zinc-based coatings.

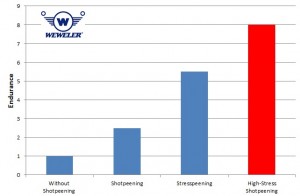

The use of new alloys in high-quality steel, a ‘Free Bending Hardening’ method (FBH) combined with high stress shot peening brought our WEWELER springs to one of the highest levels of endurance.

The key of our concept is composed out of three elements: quality, a broad assortment and fast delivery, whereby dynamical technical outlets offer a complete service and flexible solutions. The largest stock in the world of about 3500 ton, spread over more than 3000 types of WEWELER leaf and parabolic springs, adaptable to all kinds of brands (Mercedes, Man, Scania, Volvo, RVI, Iveco, Daf …), enable us to supply within 24 hours.